| How to get 5 disks into a 8 5/8 bellhousing (without buying a 9.4″ bellhousing): |

|

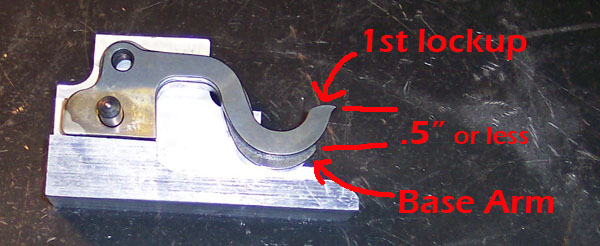

| A) release bearing clearance –> foot off of pedal, cannon extended .3 – .5″ B) base Arm offset = .1″ C) pressure plate thickness (donut) = 1.0″ D) clutch pack 3.0″ (a all new pack would be close to 4″) E) flywheel 1.15″ F) clearance flywheel to engine plate .06″ Total 5.81″ (new disks = 6.81″) Starting position for release bearing. |

|

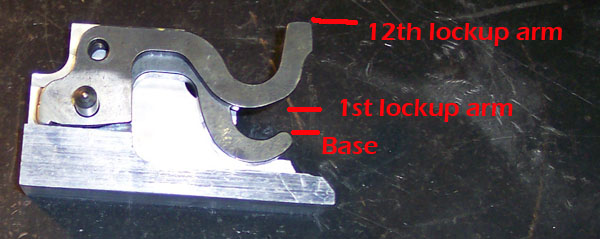

| Release bearing in picture above is touching (holding away from the pressure plate) this 1st arm, before cannon starts to move. |

|

| 12th arm 1.1 + inches (or more) from 1st arm Note all 12 arms (or whatever pp came with) aren’t required . |

| —-> initial “hit” of engine (add bending of arms,pp, flywheel etc. —-> pack clearance .050″ X the arm ratio 6 = .30″ —-> Travel of cannon (minimum) to clear arms 1.1″ total travel of cannoc1.8″ (to 2.5″) —-> wear of clutch pack during the run .08 — .18″ X arm ratio 6 = .60″ + —-> clearance after release bearing has passed all arms = ? Total distance from engine plate to front of release bearing = at least 8″ + bending, clearance+ Final position of release bearing is “outside” of bellhousing. add 1″ for all new disks or aprox .6″ less for 4 (used) disks. |

| also check clearance on cross shaft and fork *** |

|

| Add a 1/4″ spacer (alowed by NHRA) or thicker to space back bellhousing |

|

| enlarge hole in back of bellhousing, note the fork is notched to clear at bottom, and hole incudes transducer “flag” |

|

| Another spacer .5″ or more Note the bottom will have to be “clearanced” for fork |

|

| Clearance in front of cannon. |

|

| Optimizing release bearin, push tube clearances. Also depending on how much travel you need, the shaft (release bearing fork, pedal) is usually moved down in bell housing with a longer and wider fork. |

| Sheet to keep track of what you wanted / what you got after setup and shimming arms |

|