| TFX / AJPE Cast and Billet Aluminum | Oil pan rail on the windage side is moved out 1 inch to minimize damage with rod failure, also moved up to allow for more space to work. Oil gallery is between lifter bores to improve oiling over stock block ( it incorporated oil galleries with lifter bores) and supposedly an improvement over KB gallery on side of block that was inline with rod damage. Raised .250 /48 degree camshaft.

Stock height (crank to cam centerline = 5.152″) | “92” -special 92 oil pan and timing cover/ gear drive, lifter spacing is 1.8″/std. or 2.0″/spread,

426/std or 2.249/large camshaft, 2 bolt front and rear main caps.

Oil Pan Rails 11.4″ wide center to center | “96”/early -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 1.8″/std., 1.9″/spread

or 2.0″/spread,426/std or 2.249/large camshaft, 2 bolt front and rear main caps.

Light weight option available. (caps same as 92) Oil Pan Rails 10.4″ wide center to center | “96”/late -special 96 and 2000/2 oil pan and timing cover, Lifter spacing is 1.8″/std., 1.9″/spread

or 2.0″/spread,426/std or 2.249/large camshaft, 2 rear main caps and 2 through 5 caps are wider.

Light weight option available. Oil Pan Rails 10.4″ wide center to center | “2000” Billet Block (forged) -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 1.9″/spread or 2.0″/spread, 2.249/large camshaft, all main caps are 4 bolt (cross bolts). same caps as Late 96.

Light weight option available. Oil Pan Rails 10.4″ wide center to center | | “2002” Billet Block (forged) -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 1.9″/spread or 2.0″/spread, 2.249/large or 60mm camshaft, 5 main caps have fine thread tie bolts, 2 through 5 are wider with 4.400″ stud spacing (4.1″ on earlier blocks) these blocks also come with H11 studs, oiling to heads is upgraded , both banks have direct oiling from main gallery and require gallery retractors, Light weight option includes a smaller od sleave ( 4.440/4.410 ) standard blocks have same sleaves as earlier blocks ( 4.550/4.490 ) | “2013” (or 2002-rev1) Billet Block (forged) -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 1.9″/spread or 2.0″/spread, 2.249/large or 60mm camshaft

(optional 4 bolt mains ) AJPE not TFX markings | | “2013 – Light Alky” (or 2002-rev1) Billet Block (forged) -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 1.9″/spread or 2.0″/spread, 2.249/large or 60mm camshaft | | “2600” Billet Block (forged) -special 96 and 2000/2 oil pan and timing cover, lifter spacing is 2.6″/spread, x .937″ Key Way Lifter Bushings 65mm camshaft | Billet main caps and 5/8 main studs

Lifter bore centers from 1.800(std) to 2.200

Lifter bore .904 (std), 1″ , 1.062″, 1.125″

+.250 raised cam location – 48 degree

Std cam diameter , large diameter ( 2 1/8, 60mm, or 65mm )

Main journals 2.750 (std) or 3.00

Bore sizes from 4.187 to 4.500

Stock 426 Lifter Bore Spacing is .904 x 1.800″

Nitro Lifter Bore Spacing is 1″ or 1.062″ x 1.900″ (Moved away from center .050″ each way)

Alcohol Lifter Bore Spacing is .904″ x 2.000″ (Moved away from center .100″ each way) |

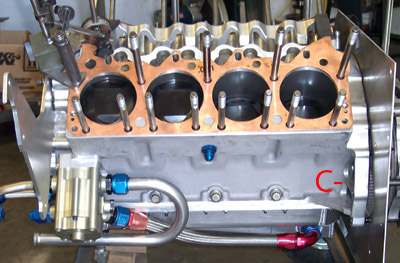

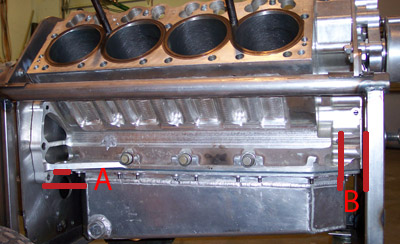

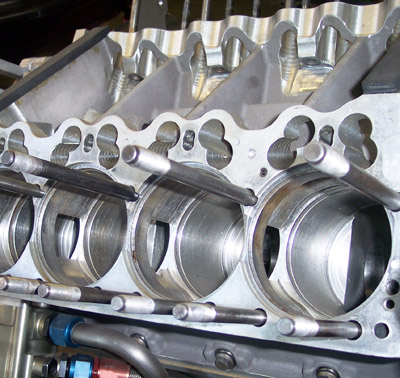

This example has been fully machined and lightened

|

This example has not been machined but note a water fitting on exterior of block

| A – tfx block is shorter and wider on bottom than original design

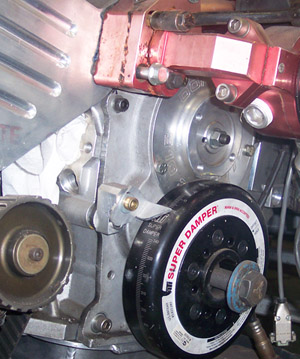

B – Front gear drive is partially built in for increased strength front of block is longer

C – starter pocket / optional ( but you can get around that problem . CLICK HERE ) |  |

The inside of this solid block has been partially machined to have a water jacket in the top part of sleeve area, it can be incorporated into a cooling system

|

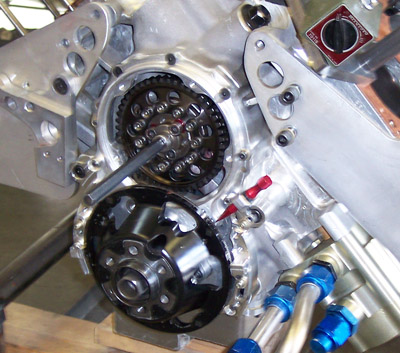

Gear drive is Partially built into block , basically a cover , gear shaft is supported in block itself. This is not interchangeable

with other blocks ( RCD and TFX make gear drives )

| TFX 2002 FORGINGS (STANDARD & LIGHTWEIGHT) MAIN CAP TORQUE

160 LBS ON MAIN CAP NUTS (WITH H-11 MAIN STUDS)

80 LBS ON FRONT AND REAR SIDE BOLTS

100 LBS ON SIDE CENTER BOLTS TFX 2002 FORGINGS ARE SUPPLIED WITH 5/16-18 X 1/2 X .045 OIL RESTRICTORS.

INSTALL ONE OIL RESTRICTOR PER SIDE. MAXIMUM TORQUE WHEN INSTALLING HEAD OR MAIN STUDS IN BLOCK SHOULD NOT EXCEED 50 FT. LBS. CYLINDER HEAD TORQUE SHOULD NOT EXCEED 140 FT. LBS ON 9/16 STANDARD STUDS,120 FT. LBS ON 1/2 STANDARD STUDS OR 160 FT. LBS ON 9/16 H-11 STUDS.

ALWAYS CHECK PUSHROD AND LIFTER CLEARENCE IN THE BLOCK, EXTRA MACHINING FOR CLEARENCE MAY BE NEEDED IN SOME CASES. CLEAN ALL TAPPED HOLES THOROUGHLY. USE EXTREME CAUTION WHEN INSTALLING STUDS IN BLIND HOLES. EXCESSIVE AMOUNTS OF OIL MAY CAUSE A HYDRAULIC EFFECT AND RESULT IN DAMAGE TO THE BLOCK. THE A-1 H-11 STUD CAN BE VERIFIED BY THE PRESENCE OF THE .250 HEX INTERNAL WRENCHING SOCKET ON THE 9/16-18 END OF THE STUD. DO NOT WASH YOUR BLOCKS WITH WATER OR WATER BASED CLEANERS WITH THE MAIN CAPS INSTALLED ON THE BLOCK. AFTER WASHDOWN, DRY AND SPRAY STUDS WITH WD-40, JB-80 OR SOME RUST PREVENTATIVE OIL. IF THESE STUDS RUST WHILE IN A TORQUED CONDITION (TENSION), CHANCES ARE THEY WILL FAIL. TFX OIL RESTRICTORS-TFX-92-96-2000

THERE IS A 5/16 – 18 TAPPED HOLE IN THE DECK OVER THE # 4 CAM BEARING, THIS HOLE HAS A ¼ – 20 TAPPED HOLE BELOW IT TO ALLOW THE INSTALLTION OF RESTRICTOR JETS BELOW THE INTERSECTION OF THE .090 ANGLE DRILLED TRANSFER HOLE FOR OILING THE ROCKER ASSEMBLY.WHEN INSTALLING THE 5/16 – 18 SET SCREW USE LOCTITE AND RUN IT JUST PAST FLUSH WITH THE DECK SURFACE, IF YOU THREAD IT IN TO FAR THE .090 TRANSFER HOLE WILL BE BLOCKED.IT IS RECOMMENDED THAT A .045 RESTRICTOR IS INSTALLED ON THE EVEN CYLINDER BANK AND NO RESTRICTOR ON THE ODD CYLINDER BANK.YOU STILL MUST PUT THE 5/16-18 SET SCREW ON THE ODD CYLINDER BANK TO CAP THE OIL GALLEY OFF.THIS IS DUE TO THE CHARACTERISTICS OF THE TFX OILING SYSTEM. |  AJPE 4 bolt Mains ( optional and can be retro fitted in some blocks ) |  AJPE – 5300 5.3″ bore spacing |

|

| Keith Black Cast and (Special Cast)Aluminum | 356 T-6 virgin aluminum (except the Stage 15 fuel block)

Bore sizes from 4.187 to 4.500

Head and main studs ½ to 9/16 or both |  |  | Since Keith Black, JP1, BAE and mopar ( world etc), share the same bolt pattern for oil pan and gear drive, they can share the hard core race items with the stock style blocks ( B, RB, and hemi) * here is a donovan gear drive with a top gear cover ( makes adjusting cam timing much easier ) from a fuel/alcohol application , it has provision for a fuel pump drive ( a cover could be purchased from the gear drive manufacture that doesn’t have this option ) , we simply modified this to incorporate a cam thrust bearing and an adjustment for it Manufactures for these include KB, BAE, Milidon, RCD , Donovan

* most of these do come in raised cam and stock cam location | Street Bore sizes from 4.250 to 4.500 Deck heights from 10.725- 10.825

Stage 3 Std cam location, water block (decks range from 10.725 to 11.225)

Stage 5 Std cam location, solid block (deck can be machined .500 short)

Stage 6 Std cam location, water block (decks range from 10.725 to 11.225)

Stage 7 Raised cam location, solid block (decks range from 10.725 to 11.225)

Stage 8 Raised cam location, water block (decks range from 10.725 to 11.225)

Stage 10 Raised cam location, water block* (decks range from 10.725 to 10.825)

Stage 15 Raised cam location, water block* (decks range from 10.725 to 10.825) “unique alloy”

| Billet main caps and 5/8 main studs standard on all Stage 10 – 15 blocks

Dual side bolts ( 6 bolt Mains) after stage 3

Lifter bore centers from 1.800 to 2.000

Lifter bore .904 (std), 1″ , 1.062″ | | Note : some stage 5 and 6 blocks came without cam bearings – camshaft runs on cast aluminum surface |

|

| BAE Cast and Billet Aluminum |  | Head studs 9/16 or 9/16 stepped to 1/2

Billet main caps and 5/8 main studs

Lifter bore centers from 1.800(std) to 2.200

Lifter bore .904 (std), 1″ , 1.090″

Std cam location, +.250 raised cam location

Std cam diameter , 2 1/8, 60mm, or 65mm

Lifter bore .904 (std), 1″ , 1.062″ |

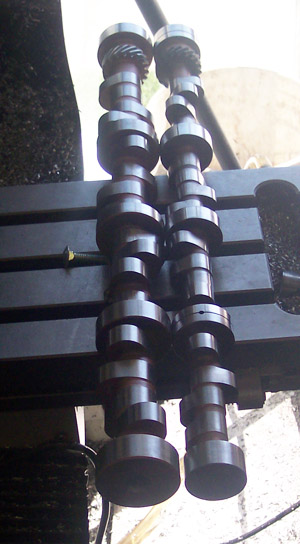

Camshaft Upgrades in size and Location |

|

| CN Blocks Billet Aluminum | Premium CN Billet material

Deck heights: 10.725”, or 10.825”

Standard Chrysler main size

All five main caps are cross bolted

9/16” tool steel main studs, 1/2” side bolts

+.250 Cam height

Cam journal size: 2 1/8, 60mm, or 65mm

Lifter spacing: 1.900”(+.100 spread), or 2.00” (+.200 spread)

Lifter size: .904”, .936”, 1.0”, or 1.062”

GM starter mounts

( Can be modified to clear Chrysler starter )

•Dry block

•Chrysler and GM bell housing pattern

•Stock Hemi or CN Blocks wide pan pattern

|  | | |

|

| JP1 Cast Aluminum | Head studs 1/2

Lifter bore centers 1.800(std)

Lifter bore .904 (std)

Std cam location,

Std cam diameter | | | | | | | | |

|

Consider a Keith Black aluminum street HEMI block. | Mopar Steel Aluminum | Casting #2468330 1964-1971 426 Hemi

Head Bolts ( studs cannot be used ) 7/16

Lifter bore centers from 1.800(std)

Lifter bore .904 (std)

Std cam location, +.250 raised cam location

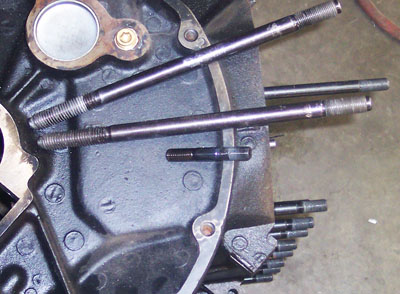

Std cam diameter , large diameter |  | Just a quick observation of the basic difference in stock style and real race products, the top studs are the minimum size of a race aftermarket block, bottom little stud is the

maximum holding device for stock style |

|

| Donavan Cast Aluminum 392 Hemi ? | Head studs 1/2

Lifter bore .904 (std)

Std cam location,

Std cam diameter | This is an aluminum replica of the 1st generation HEMI 354, 392 etc

with a main cap girdle built in, which is loosely based on the LA small block

( or the other way around ) |

|

|